|

1.Product introduction

BHT is traditional feed and food antioxidants, and are widely used in different industries (nearly 220 product areas) such as food, feed, oil, cosmetics, medicine, biologics, synthetic rubber, and plastics. BHT has been in industrial production in Germany for more than 80 years since it was industrialized in 1937. Moderate price and superior performance (the world's first usage rate in oil products) have proven to be a safe, efficient and stable antioxidant. Using our fresh antioxidant products can reduce the risk of feed oxidation and ensure feed quality and safety.

2.Product Features

1 、Better contact, longer effect

BHT is made into a fine-crystalline powder through a special process, which increases the number of particles per gram of BHT by 20-30 times, greatly increases the area of contact with the feed, improves fluidity, ensures uniform mixing in the feed, and enhances the antioxidant effect .

2、Excellent protection for grease

Oxidative rancidity of fats and oils is the most susceptible oxidation process in feed. BHT is a phenolic antioxidant that releases hydrogen ions and combines with free radicals to turn them into inert compounds, protecting oils from damage.

3、Easy to penetrate into the material

BHT's unique physical properties can penetrate into the material during the pelleting process of the feed and exert its antioxidant effect.

4、Keep the food high-quality appearance

There are a large number of metal ions in the feed, and some varieties of antioxidants will react with them to form colored complexes, while BHT will not interact with metal ions to form colored substances, and it will not change the appearance and color of the feed. BHT is odorless and tasteless, and does not react with other substances to form odorous substances, ensuring the commercial quality of feed.

3.The automatic oxidation of feed and its raw materials

1、 The automatic oxidation of feed is a complex process that destroys the chemical structure of organic nutrients. It will not only reduce the use value of fats, vitamins, pigments, and flavoring agents, but also produce bad smells and toxic substances due to oxidation, which will lead to animal feed , Digestibility, health and productivity are adversely affected.

2、Oxidation hazards of feed

a.Nutrient loss, poor palatability, toxic substances, short shelf life

b.Lack of nutrition, inhibited growth, inflammatory response, poisoning, food safety

c.Economic loss

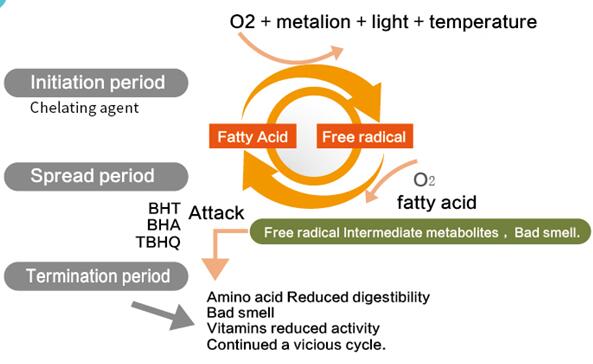

4.The process of oxidation and the role of antioxidants

Initiation period: Various fatty acids and other easily oxidizable feed ingredients are oxidized under the induction of metal ions, light and temperature to generate oxygen free radicals.

Propagation period: The oxidation intermediates react with oxygen free radicals to produce corruption products such as aldehydes and ketones.

Termination period: The oxidation intermediates react with organic nutrients such as vitamins and amino acids to produce products such as amines, and then continue the vicious cycle in geometric multiples.

5.AOZOA® A60 product composition analysis

|

Name |

Product ingredients |

Other |

|

AOZOA® A60 |

BHT≥60% chelating agent |

Dispersing agent, etc. |

Hygienic indicators and moisture reach to national regulations.

Physical and chemical properties:

Main ingredients and content: Dibutyl hydroxytoluene (BHT) ≥60%

Color: white or off-white

Properties: powder

Solubility: insoluble in water, soluble in fat and most organic solvents

Particle size: 80% over 60 mesh, 40 mesh sieves ≤10%

6.Safety

AOZOA® A60 uses food-grade antioxidants: BHT is an antioxidant allowed in feed and food (GB2760-2014).

7.Dosage (g / T)

|

Feed category |

Full-Price Feed |

Concentrated Feed |

Pre-mixed Meat |

Bone Meal |

Fish Meal |

|

Dosage per ton (g) |

100-200 |

200-500 |

200-500 |

400-500 |

500-700 |

Adding suggestions: Antioxidants should be added before the feed undergoes oxidative deterioration to exert its antioxidant effect. The number of antioxidants should be determined based on factors such as fat content and mineral content in the feed, and environment and time during which the feed is stored.

Storage: Ventilated and stored in a dry and dark place

Packing: 20KG Plastic woven sack

Shelf life:24 months.

If the color changes during the warranty period, it will not affect the use of the product.

|